Flywheel Balancing Machines | Universal Balancing

Balancing machines for flywheels and flexplates. Automatic single or multi-station balancing machines designed for high volume production lines. Intelligent in-process feedback optimizes production throughput and reduces rejects. Ultra-high accuracy and repeatability of <10% part tolerance. Industry leading cycle time.

Speak with an ExpertSummary

Our range of vertical balancing machines for flywheels and flexplates have industry leading measurement accuracy and repeatability, exceeding industry process capability assessment requirements as standard.

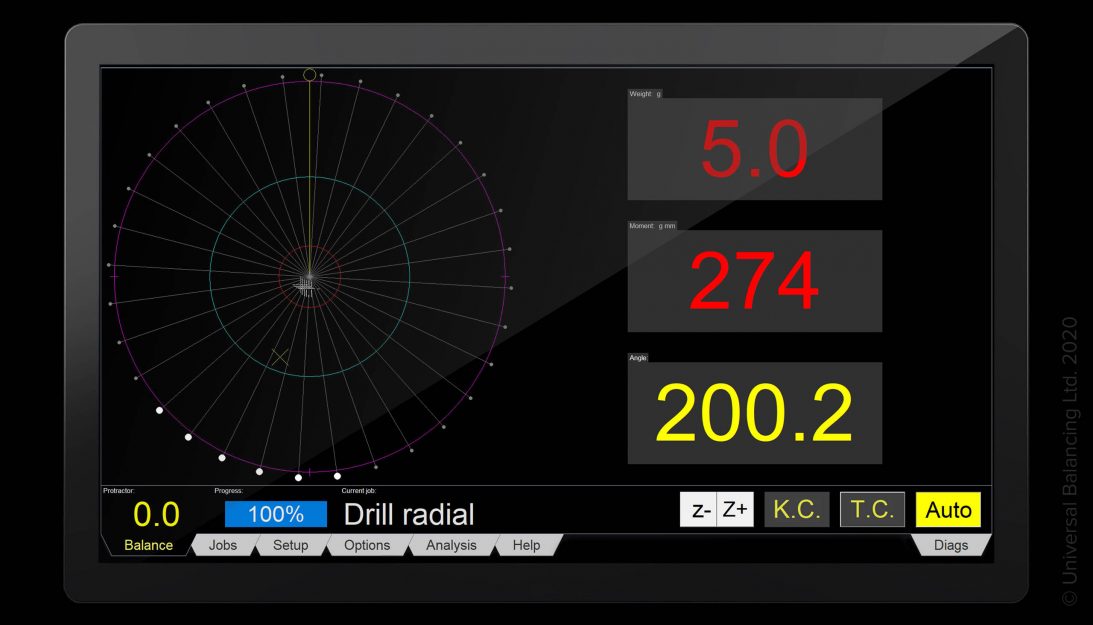

Flywheels and flexplates are typically balanced with drill correction although other correction methods are available such as milling and welding. All correction methods have intelligent feedback ensuring high quality unbalance correction, increased machine throughput and reduced rejects.

Single station and multi-station variants are available for different batch sizes and production demands. Supplied as stand alone machines for manual loading or to be integrated into customer automatic work cells, or offered as a full turnkey solution including robots, conveyors or pick and place gantries.

Our flywheel and flexplate balancing machines come with the industry’s leading measuring system and balancing software, UNI-64 and Winbal. Winbal includes error proofing of setups and operation, features to improve cycle time, prompt routine maintenance checks and comprehensive industry 4.0 in-built diagnostics functionality and much more.

All our balancers have a small footprint as standard, are installed and commissioned in as little as 1 day and are built largely with industry standard components.

When support is required, our engineers are hand 24/7 to remotely connect to the machine to resolve as many as 90% of all issues. When a site visit is required, our global network of support engineers are available for rapid dispatch.