Summary

XL Machine’s skilled machinists and precise CNC machinery will produce your parts to exact specification, and our Quality Team will ensure that accuracy prior to delivery.

The core of our strategy begins with our strong Quality Team. Functioning as your internal advocate they work continuously to ensure the quality of your parts. Whether that is through system improvements, incoming inspection, in-process or outgoing inspection, we have you covered.

Our day-to-day quality is driven by a number of AIAG systems. For example, Advanced Product Quality Planning (APQP), Production Part Approval Process (PPAP), Process Control Plans, Process Flow Diagrams, PFMEA and Process Capability Studies. These systems create the repeatable structure that you want.

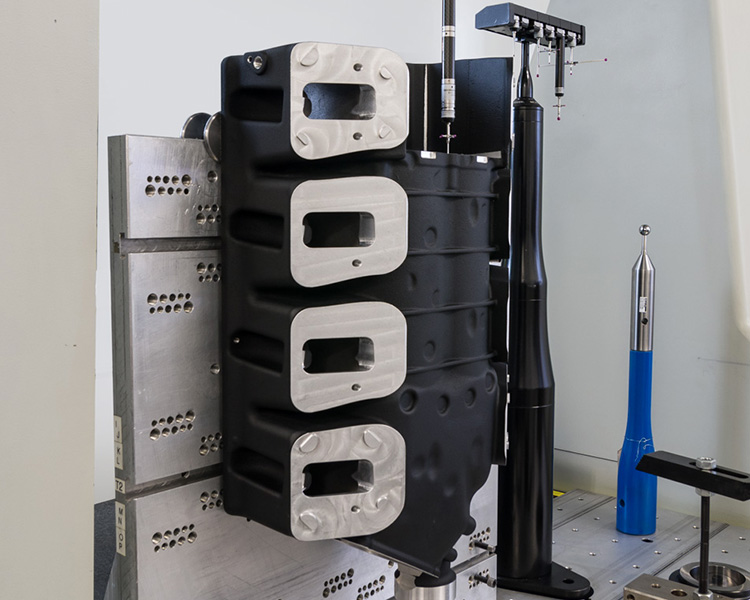

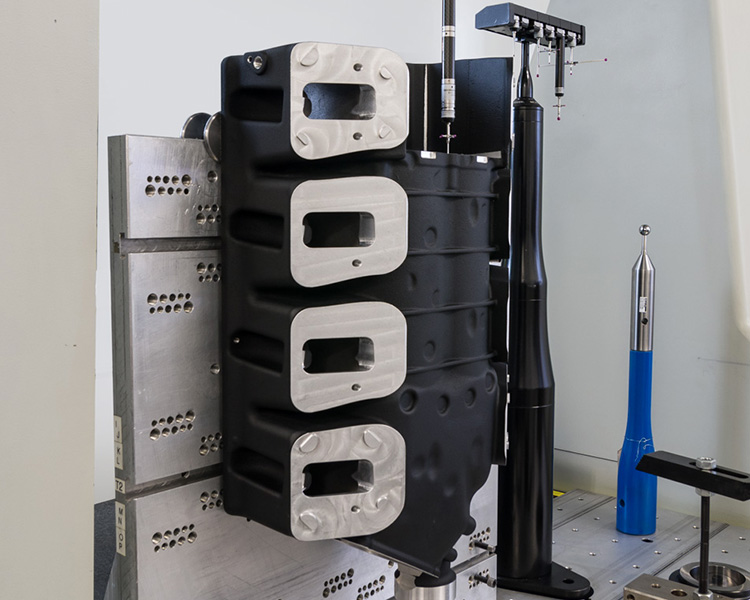

And finally, our eleven (11) coordinate measuring machines (CMM) give us the necessary tools for precise detailed inspections. XL Machine is IATF 16949:2016 registered. You expect quality. At XL Machine, we deliver it.

Details

Precision Measurement Specifications

XL Machine delivers standard volumetric accuracy up to .0065mm and repeatability of .002mm

- CMM Services

- Keyence Capabilities

- Hardness Testing

- Performance Repeatability