CNC grinding

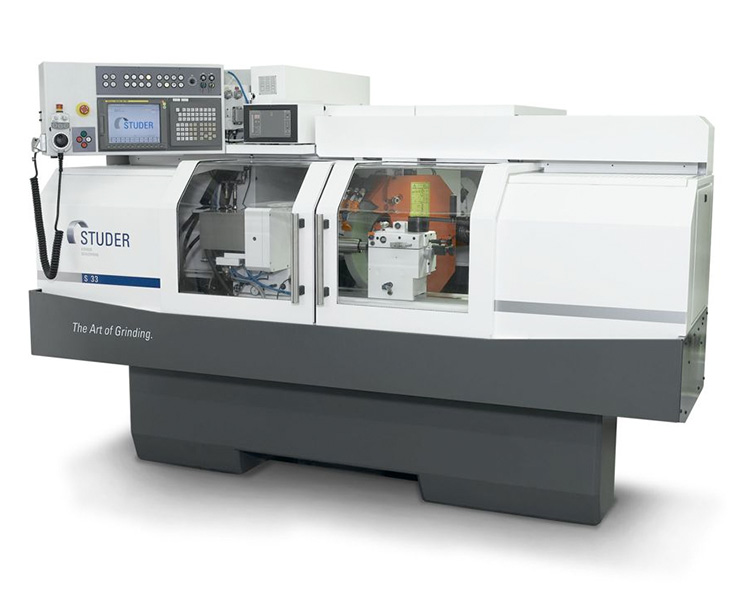

XL Machine utilizes a state-of-the-art Studer S33 Universal CNC Grinder to provide high precision parts with minimal lead time. This machine is ideal for prototypes, tooling, specialty and low to medium volume production.

Overview

XL Machine utilizes a state-of-the-art Studer S33 Universal CNC Grinder to provide high-precision parts with minimal lead time. This machine is ideal for prototypes, tooling, specialty work, and low- to medium-volume production.

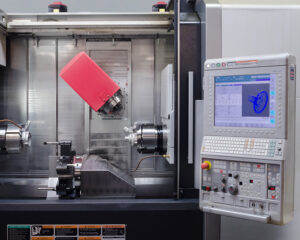

A major benefit of the S33 is the turret-style wheel head, which provides unmatched geometric tolerances of work in a single clamping by utilizing three grinding wheels in one operation. This machine also has diamond and CBN superabrasive capability with rotary diamond dressing to meet extreme tolerances and maximize productivity.

Product Details

- 13.75” Maximum OD

- 40” Max Length between Centers

- 8.0” Max ID x 8.0” Max Depth

- CNC Wheel Profiling

- Multi-angle Use of Wheels

- Active Part Probing

- .0001mm Tolerance

Frequently Asked Questions

Ascential T&M utilizes a state-of-the-art Studer S33 Universal CNC Grinder to provide high precision parts with minimal lead time. This machine is ideal for prototypes, tooling, specialty work, and low to medium volume production.

Ready to upgrade your infrastructure?

Contact our engineering team for a custom quote or technical consultation regarding CNC grinding.

Related Products

Assembly

XL Machine provides even more value through our assembly services. These services… Assembly

CMM quality

XL Machine’s skilled machinists and precise CNC machinery will produce your parts… Precision Machining

CNC milling

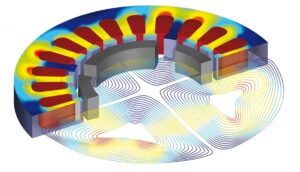

Magnetization system for permanent magnets serving power station generators (megawatt scale) to… Precision Machining