Event

RSVP for limited access to our “Excellence in Balancing Training” experience

Learn balancing best practices for applications for turbo and heavy-duty applications in agriculture, aerospace, turbo systems, and industrial equipment.

Register today for an open house: - Tue Jul 15 from 11a–4p CT

- Wed Jul 16 from 9a–2p CT

- Thu Jul 17 from 11a–4p CT

Whether you need to increase precision or decrease costs, our custom, made-to-order products can help you optimize any operation. Below are a few examples of engineered solutions that are made possible by modifying our line of standard products.

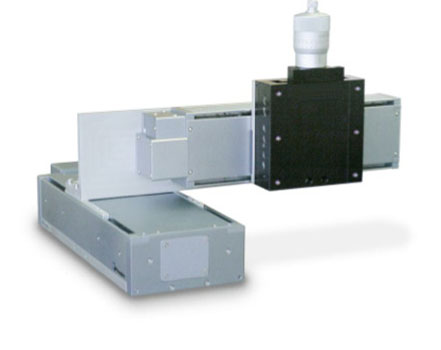

MODIFIED PLG160

Here we have taken a PLG160 and modified it for two carriages and used for printhead assembly. The PLG160 is equipped with a single encoder and dual forcers to track and limit sensors between carriages to avoid collision.

XYZ STACK

This XYZ stack, with third-party manual Z axis, is employed as a semi-automated tester by a printer manufacturer.

XYZ-THETA STACK

This four axis XYZ-theta stack, with two custom brackets, was engineered for an inspection machine to carry sensors over DUT.

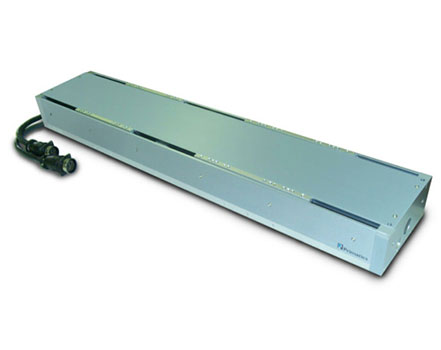

1200 MILLIMETER LINEAR STAGE

This 1200 millimeter linear stage is based on a PLG160 with a PLG110 frameless motor to be used in a large format material deposition machine.