STANDARD BALANCING SYSTEMS

Precision component balancing across aerospace and transportation applications

Balancing questions? Done.

Ascential Virtual Assistant

Sentia AI

Have an impossible question about balancing? Ask Sentia, and let's start making it possible.

You can ask questions like these and much more.

Please fill out the form below to download your chat log.

Solutions from our leading balancing brands

We collaborate with you at every stage – from needs analysis, through designing dedicated solutions, to service and upgrades. Our experience encompasses thousands of implementations in facilities worldwide.

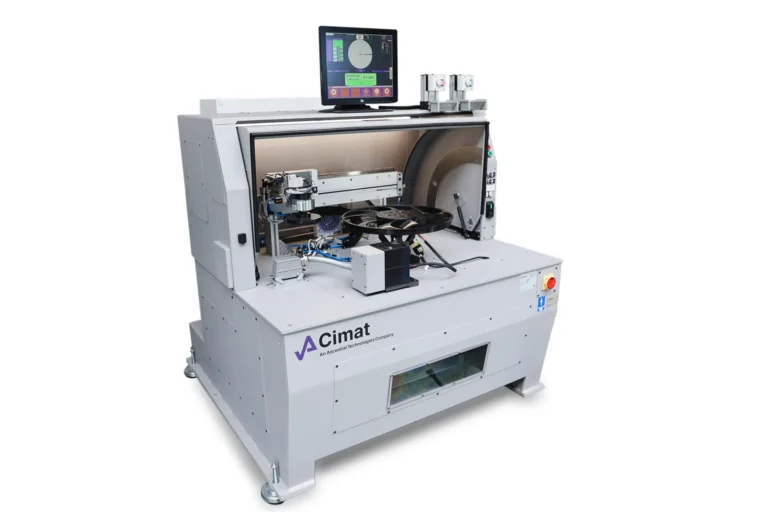

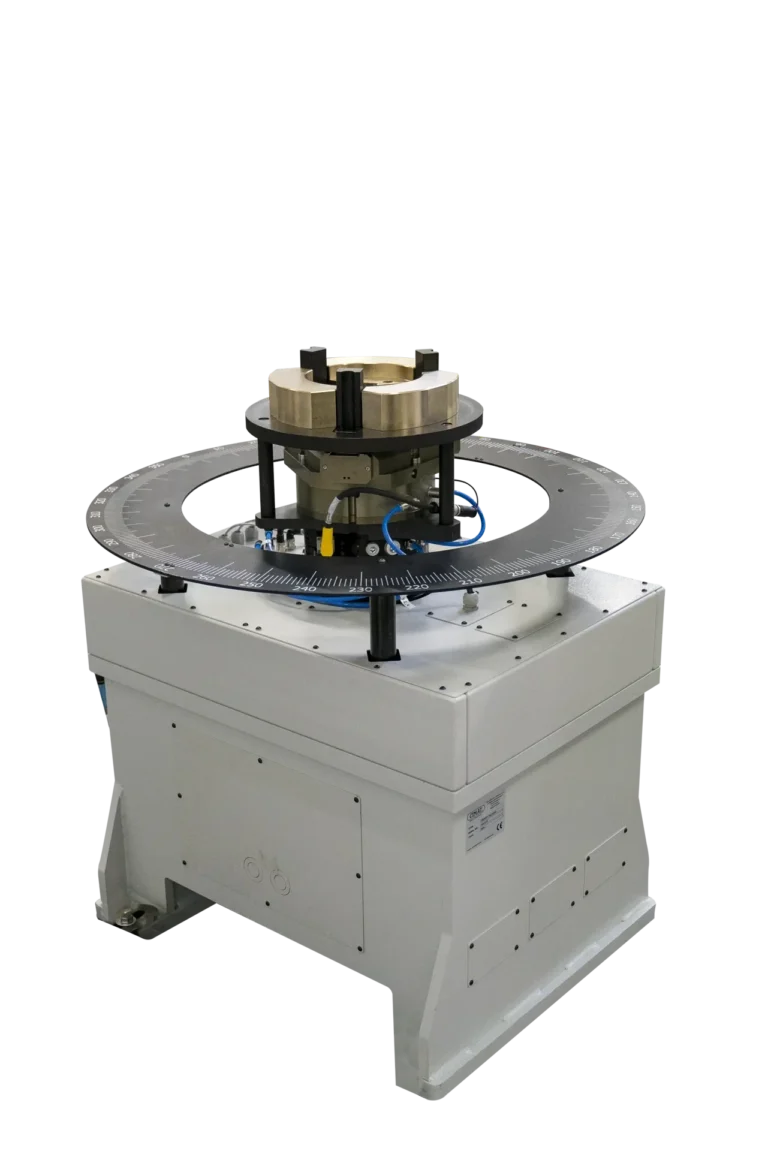

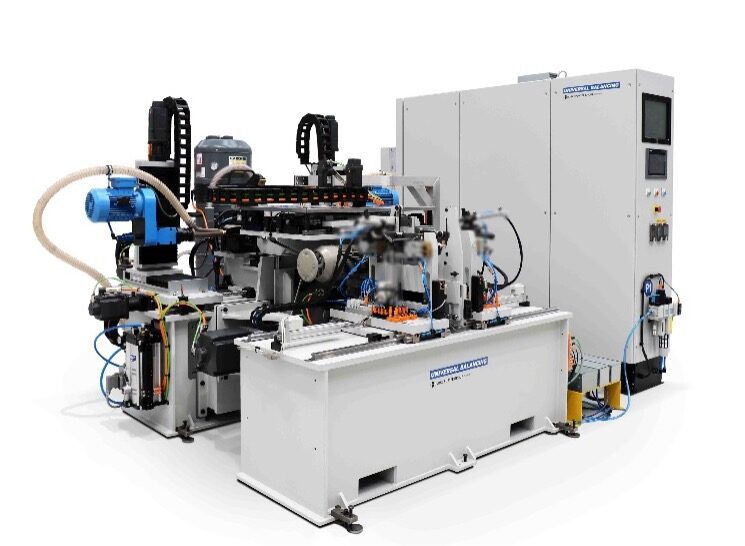

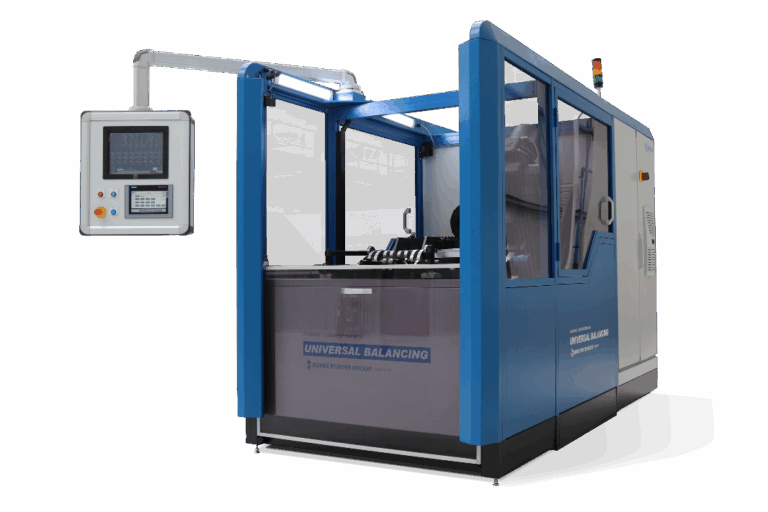

axis balancing machines

- Rigid, cast-iron housings dampen vibration and reduce environmental sensitivity.

- No foundation or anchoring required — ready for deployment in standard facilities.

- Fully enclosed drive system isolates the rotor for precision feedback.

- Optional pneumatic or motorized clamping for faster setup cycles.

- Supports manual, semi-automatic, and fully automated correction modes.

- Closed-loop unbalance detection with adaptive speed control for faster cycle times.

- Integration-ready with industrial robots and automated handling cells.

- Real-time process monitoring through Ascentialytics for predictive maintenance.

- All balancing data stored locally and synced to network databases for traceability.

- Comprehensive reporting of unbalance trends, machine health, and operator efficiency.

- Workshop subroutines calculate corrections via multiple methods — drilling, milling, or weight adjustment.

- Secure data export via Ethernet or API connection for MES/ERP integration.

- Automotive: brake discs, flywheels, dual-mass wheels, and pulleys.

- Energy: compressor rotors, turbine impellers, and pump rotors.

- Machinery: gears, sheaves, and couplings for industrial use.

- Electronics: precision components including drives and small rotors.

- Manual: automated measurement with manual positioning — ideal for small series.

- Semi-Automatic: automated correction with manual part handling — optimized for mid-volume production.

- Fully Automatic: complete cell with robotic feed, correction, and unloading — maximum throughput with minimal operator input.

Engineered for dynamic precision and built to master complexity

Vertical axis balancing machines deliver consistent, repeatable performance for disc-type rotors without journals. These systems combine robust mechanical design with adaptive software and automation options, creating a platform that scales from manual use to fully automated production. The result: greater throughput, higher accuracy, and total confidence in every component leaving your line.

Engineered for dynamic precision and built to master complexity

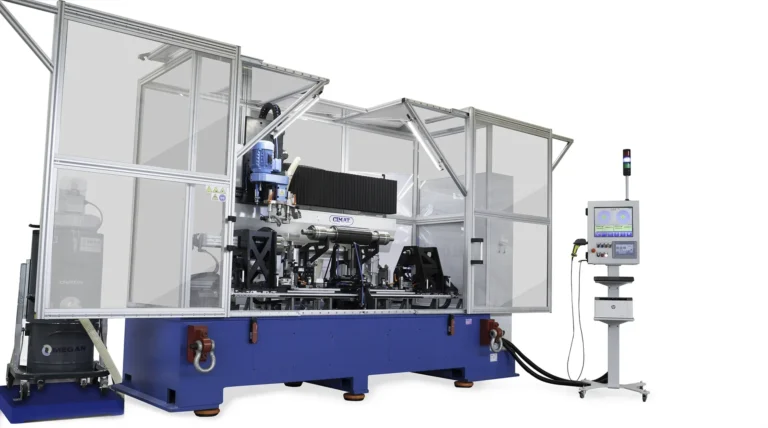

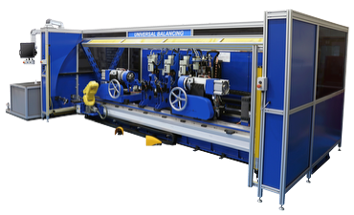

Built for versatility and precision, our horizontal axis balancing machines deliver professional-grade performance for rotors supported on their own journals. Designed for multi-plane balancing and adaptable to nearly any rotor geometry, these systems combine mechanical rigidity with intelligent measurement and control. Each machine is engineered for durability, repeatability, and rapid cycle times — from prototype through full-scale production.

axis balancing machines

- Balances components in a position identical to real operating conditions.

- Handles a wide range of rotor shapes and dimensions through advanced tooling systems.

- Supports multi-plane balancing for extended rotors and shaft assemblies.

- Short measurement cycles maximize uptime and reduce balancing cost per part.

- Equipped with industrial touch-screen LCDs for real-time visualization and input.

- Dual calibration capability — factory hard calibration and user soft calibration.

- Unbalance detection modules with ultra-fast signal acquisition and DSP correction.

- USB, Ethernet, and laser printing built in for data export and report generation.

- Software includes subroutines for drilling, milling, weight shifting, and compound corrections.

- Rigid steel frames minimize environmental vibration and support long service life.

- Modular design enables later addition of extended beds or auxiliary drives.

- High-precision bearing supports ensure consistent alignment and repeatability.

- Integrated guarding meets ISO 7475 / DIN 45690 safety standards.

- Each machine is configured to align with customer-specific process requirements.

- Includes commissioning, operator training, and on-site production integration.

- Full modernization and upgrade support through the Ascential Care program.

- Rapid-response service for warranty and post-warranty maintenance.

- Aerospace: drive shafts, transmissions, starter rotors.

- Energy: generator rotors, turbine shafts, and pump assemblies.

- Shipbuilding: propellers, electric motor rotors, and separators.

- Automotive: crankshafts, EV rotors, and transmission components.

- Remote monitoring, real-time diagnostics, and system health tracking.

- Predictive maintenance driven by performance data analytics.

- Automated reporting and production traceability.

- Native integration with MES and ERP systems for Industry 4.0 compliance.

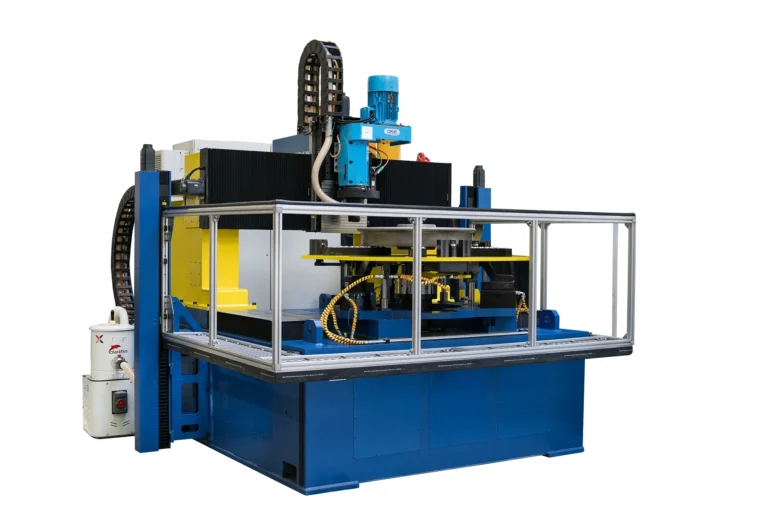

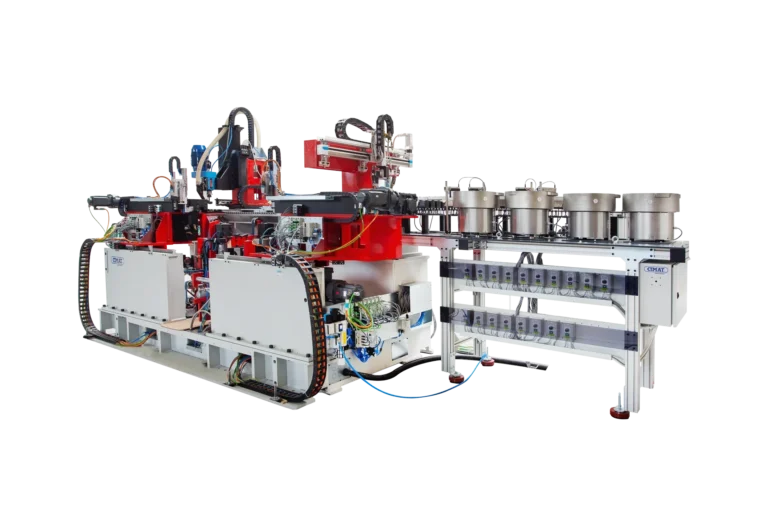

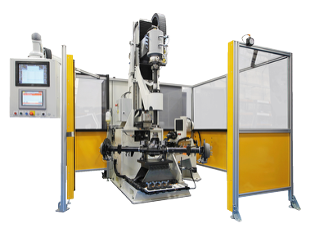

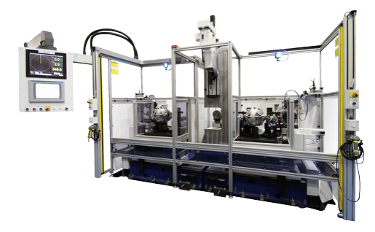

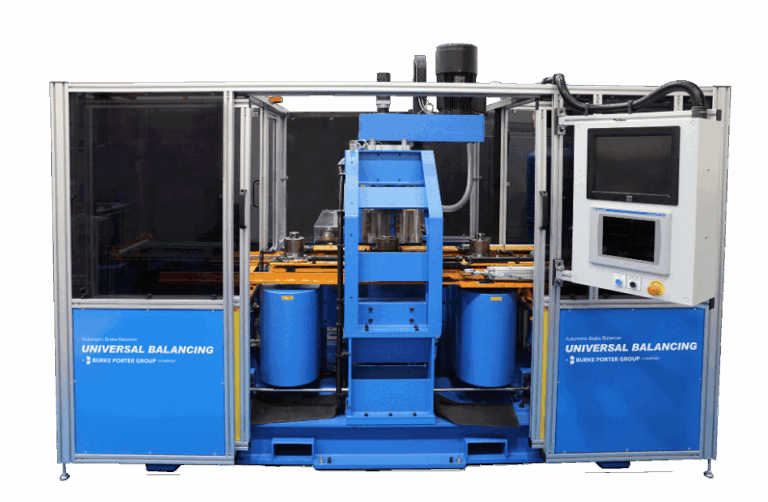

and semi-automatic balancing machines

- Automatic and semi-automatic systems for vertical or horizontal rotor axes.

- Supports drilling, milling, welding, adhesion, or mass removal correction methods.

- High-throughput operation with built-in error compensation and calibration logic.

- Remote service connectivity for live diagnostics and performance tracking.

- Automated residual unbalance analysis with adaptive learning across production runs.

- Procedures for fixture error compensation, forbidden zone management, and automatic calibration.

- Data recorded for every cycle, stored locally or network-wide for analysis and reporting.

- PLC-based motion and measurement coordination ensures stable process timing and repeatability.

- High-reliability components from Siemens, Allen Bradley, and Fanuc guarantee uptime.

- Automatic measurement and diagnostics managed by an intelligent control computer.

- Operator-assisted handling with automated correction and verification cycles.

- ISO 21940-compliant measurement protocol generation with ERP export capability.

- Optimized for mid-volume production environments requiring flexibility and throughput.

- Applications include brake discs, flywheels, clutches, crankshafts, and electric motor rotors.

- Complete cycle automation — loading, measuring, correction, and final sorting.

- Zero-operator process with cycle times optimized for high-volume automotive lines.

- Real-time feedback loops adjust spindle speed and correction force dynamically.

- Built-in quality assurance: automated verification of every component before discharge.

- Industry 4.0 connectivity: full MES, SCADA, and Ascentialytics integration for production traceability.

- Automotive / E-Mobility: brake discs, dual-mass flywheels, rotors, crankshafts, alternators.

- Machinery & Pumps: spindles, pulleys, impellers, electric drives.

- Aerospace: transmission shafts, turbine sub-assemblies, and other precision rotors.

- Railway: wheelsets, traction rotors, and drive aggregates.

- System configuration tailored to each customer’s production environment.

- Commissioning, training, and production-line integration provided turnkey.

- Standard inclusion of C60 guards meeting ISO 7475 / DIN 45690 safety codes.

- Full lifecycle modernization, warranty, and post-warranty service through Ascential Care.

The next generation of precision, built for scale and consistency

Automatic and semi-automatic balancing systems merge advanced measurement, control, and automation into one continuous process. Designed for high-volume production, these machines deliver reliable, repeatable balance across thousands of parts per day. Every system reflects deep engineering integration — from servo-driven spindles and adaptive correction algorithms to real-time analytics and closed-loop process control.

Precision anywhere, performance without boundaries

Portable balancing machines bring the power of advanced diagnostics directly to the source. Built for mobility, accuracy, and speed, these systems let technicians analyze, correct, and document unbalance in the field — without removing the rotor. From turbines and fans to drive shafts and couplings, every reading delivers reliable, repeatable data that keeps operations running and downtime low.

balancing machines

- Portable systems enable single- and dual-plane balancing without removing the rotor.

- Performs FFT and vibration analysis across the 10–1000 Hz range for full dynamic evaluation.

- Automatically classifies vibration severity according to ISO 2572-1974 standards.

- Compact design with solid-state memory and intuitive control interface.

- Measurement data stored locally or exported wirelessly for remote reporting.

- Quick on-site balancing for rotors of any mass or geometry.

- Immediate intervention in vibration events to prevent production downtime.

- Universal compatibility with industrial fans, pumps, pulleys, and motors.

- Supports protocol generation and printing via any connected PC or Wi-Fi printer.

- Performs FFT analysis for both time and frequency domains.

- Bearing diagnostics with access to a 30,000-entry bearing database (optional).

- Multi-plane balancing for rotating assemblies under real operating conditions.

- Stores and classifies machine condition results as Good, Satisfactory, Temporarily Acceptable, or Unacceptable.

- 6-hour battery life supports extended field operation.

- IP65 protection against dust and water ingress.

- Operating temperature range: -10 °C to +40 °C.

- Solid-state 64 GB SSD ensures secure data retention.

- Ergonomic navigation keys and a large illuminated display for low-light conditions.

- Standardized vibration measurement compliant with ISO standards.

- Data export and documentation via USB, Wi-Fi, or local network connection.

- Simple navigation interface for fast operator training and setup.

- Fully compatible with Ascentialytics for remote monitoring and data trending.

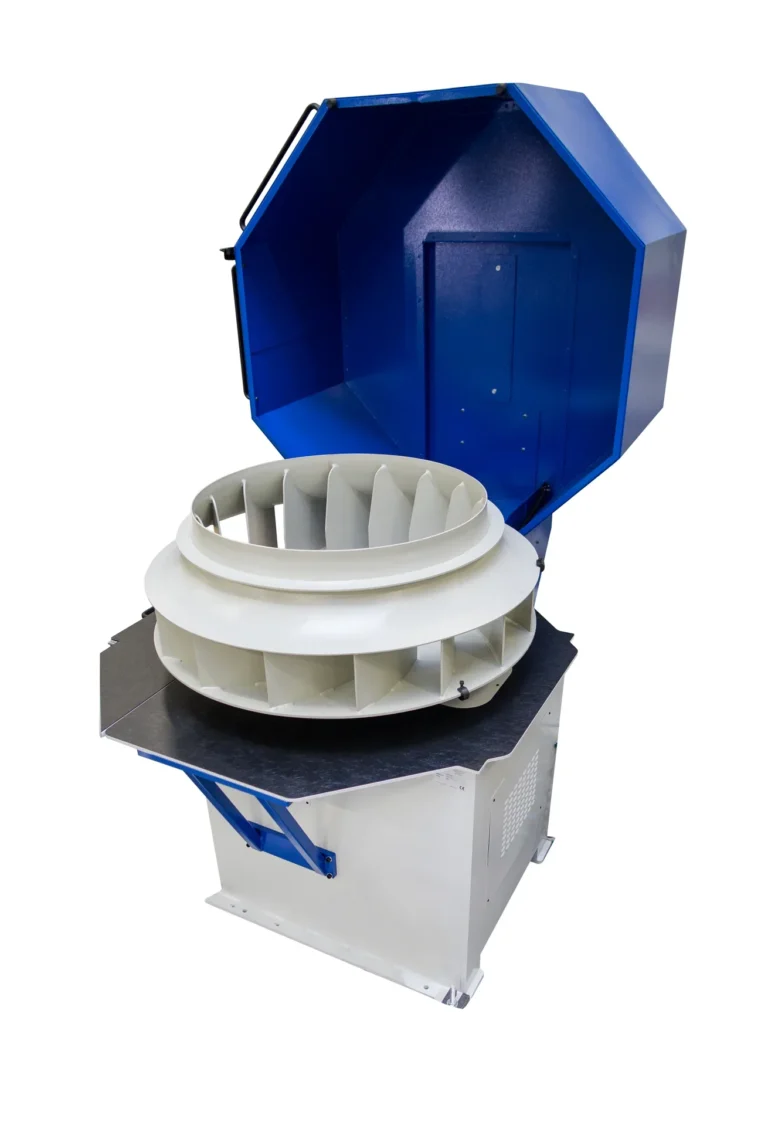

vertical non-rotating balancers

Engineered for precision and built to master complexity

Our experience is unmatched in delivering precision static balancers. Our solutions provide ultra-high accuracy, repeatability, rapid cycle times, and flexible configurations — all within a compact footprint and with exceptional ease of use.

Our range of static, stiff-pivot, non-rotating, and rotating vertical balancers are designed to measure unbalance in disc-type rotors up to 1,500 kg . From stand-alone manual systems to fully automated solutions, each balancer can be integrated with off-machine drills, welders, or other correction tools for complete process efficiency.

balancing applications

Brake systems

ADAS

Engine test

Power take-off unit (PTO)

Tire and wheel

Driveshaft

Tire and wheel

Front and rear axle

Brake systems

Front and rear e-axle

Battery systems

Front and rear drive module

Tire and wheel

E-motor and inverter

ADAS

Brake systems

E-motor and inverter

ADAS

Front drive module

Rear drive module

Tire and wheel

Battery systems

Unmatched automotive balancing excellence

Balancing is critical to the accuracy, durability, and performance of today’s automotive components. From engine rotating assemblies to driveline and chassis parts, even the smallest imbalance can create noise, vibration, premature wear, and reduced vehicle quality. We deliver a comprehensive range of high-specification balancing systems engineered specifically for automotive manufacturing. Our results ensure precision-balanced automotive components, higher production throughput, and lower operating costs across your entire manufacturing line.

About the Balance Tolerance Calculator

This tool helps you determine the permissible residual unbalance of a rotating component, expressed in gram-millimeters (g·mm). By entering the balance quality grade (ISO 1940/1 standard), the component’s operational speed (RPM), and its weight (kg), you’ll get a calculated tolerance value.

This tolerance represents the maximum allowable imbalance that can remain in the part after balancing. Staying within this range helps reduce vibration, extend bearing life, and improve overall machine performance.

Tolerance Calculator

- Single and dual-plane balancing

- FFT analysis

- Measurement of effective machine vibrations in the 10-1000Hz band; the instrument (in accordance with ISO 2572-1974) will classify its condition on a four-level scale as: good, satisfactory, temporarily acceptable, or unacceptable.

- Bearing condition analysis program – Option: database of approximately 30,000 bearings

- Balancing of rotors of any mass and shape directly in the machine. The rotor is not removed from the machine!

- Protocol printing via any PC computer or WiFi printer. All measurement activities are stored in the instrument’s data memory at the operator’s request.

Mobility Advantage in Industry

- Speed of response – Ability for immediate intervention when vibration problems occur, minimizing production downtime.

- Universal application – the portable device handles a wide spectrum of applications – e.g., fan rotors, pulley wheels, instruments, and many other components.

Standard Set

- Operating time: 6 hours on battery

- IP65 protection rating

- Temperature range: -10°C to +40°C

- SSD 64GB

The SmaRT advantages:

- Easy operation with the aid of navigation and function button

- Large illuminated color display

- Standardized vibration measurement

- Simple transfer and documentation of measurement results

Why do industry

leaders choose us?

Precision at the highest level – Our balancing machines achieve balancing measurement accuracy of 0.1 g·mm, which translates to exceptional end-product quality. Our machines find applications in the aviation, automotive, energy, shipbuilding, mining, ventilation, paper, machinery, tooling, armament, agricultural industries, pump manufacturers, and many other industrial and craft sectors. Technology tailored to needs – From compact universal balancing machines to fully automated specialized production lines that are adapted to the industry or individual customer needs. After commissioning the balancing machine, we help the customer implement it into operation. Our production and service offering, from the perspective of balancing machine purpose, is virtually unlimited.

How is

balancing critical?

The balancing process is a crucial element of every production or operation process involving rotating components. An important aspect of balancing is also that equipment used in production processes requires regular diagnostics to operate properly and remain resistant to failures. The best solution is to implement preventive measures that will protect them from breakdowns and costly production downtime.

Our production offering is virtually unlimited

Comprehensive service

- We adapt the machine to the technological requirements of the customer.

- Unbalance correction available in manual, semi-automatic, or fully automatic modes.

- C 60 type guards supplied in accordance with ISO 7475 and DIN 45690.

- We commission and implement the machine into production.

- Fast warranty and post-warranty support through manufacturer service.

Special features

- Balance in one or two correction planes.

- Electronic angular scale allows rotor angle monitoring post drive stop.

- Automated operation for maximum precision.

- Measurement results recorded in machine database.

- Workshop subroutines calculate unbalance via drilling, milling, or redistribution.

Typical applications

- Automotive: brake discs, flywheels, clutches, pulleys.

- Energy sector: compressors, turbines, pumps, impellers.

- Machinery: gears, pulleys, rotating components.

- Electronics: hard drives, precision device rotors.

Available configurations

- Manual balancing machines – automatic measurement, manual correction, ideal for small/medium series.

- Semi-automatic systems – automatic correction, manual load/unload for cost-efficiency.

- Fully automatic lines – integrated balancing stations with automatic correction and feeders.

Our standard balancing machines are ready to go when you need them most

Whether you’re facing a challenge that calls for a custom-engineered solution or you quickly need a reliable, off-the-shelf system, we’ve got you covered.

Our Cimat and Burke Porter, formerly known as Universal Balancing in the UK, branded balancing machines cover a wide range of applications—designed with the same precision, built with the same commitment to excellence. Consider some of the examples below, but to see our broader offering, visit our applications and resource hub.